The specific need to obtain circles, spirals and centrings from big diameter rods, manifested through the years from several professionals of the field, brought OF.ME.R. to include in the own range the Spiral Machine CAL34. Easy to use and with a very interesting price, is a good alternative to the classical calendering systems available on the market, enjoying high approval among the Italian and foreign companies that have chosen this product to carry out their projects.

This special machine allows to calender rods with diameters from 6mm to 32mm. The two-speed motor gives at the same time the speed to bend smaller diameters and the power to process the largest ones.

The CAL34 allows to execute circles with unlimited curving radius (irons for centrings) and spirals with adjustable diameter from a minimum of 15cm to a maximum of more than 200cm. Even the pitch of each spiral is totally adjustable, thanks to the appropriate mushroom device.

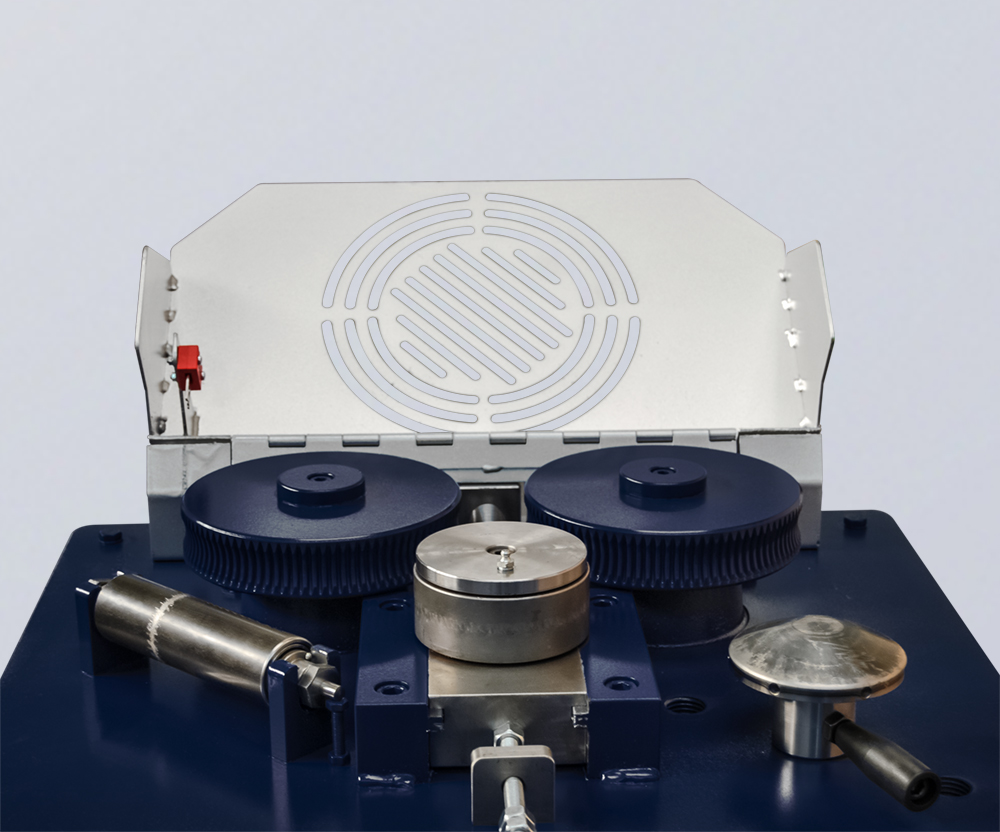

The working top is constituted by three rollers, placed in triangular position, all of them in a special heat treated alloy. The two largest ones, named “towing rollers”, are provided with manifold inclined slots, with the function to catch the bar; the central roller, called “idle roller” and adaptable through the specific screw, has the role to determine the curving radius.

Depending on the requirements, the Spiral Machine CAL34 can be prepared to work in horizontal or vertical position.

This unit, that allows to elaborate rods up to a maximum diameter of 32 mm, is ideal for medium/large building sites, but is also excellent for less structural works, such as the support spirals for pillars, where it guarantees the maximum performance.

The double-speed motor, selectable by the electrical panel of the spiral machine, makes it possible to work small diameters very quickly (choosing the maximum speed) and calender larger diameters in total safety (using the reduced speed).

Standard Equipment:

- A set of Allen keys, for ordinary maintenance;

- A double electrical pedal, that allows to activate the towing rollers clockwise (yellow pedal) or counterclockwise (blue pedal);;

- A set of wheels, for the machine handling;

- An industrial plug, that guarantees the electrical connection;

- Two mushroom button switches, to immediately stop the machine in case of emergency. They are positioned on two opposite sides of the machine.

In the design and construction of each mechanical spiral machine have been adopted criteria and arrangements suitable to satisfy the essential safety requisites foreseen by the Machines Directive 98/37/CEE.